On Time. In Spec. Every Time.

We’re not just fabricators. We’re professional problem solvers ready to help solve your complex metal part challenges.

Get the part you need, the day you need it, the way you specified it.

Why Haake

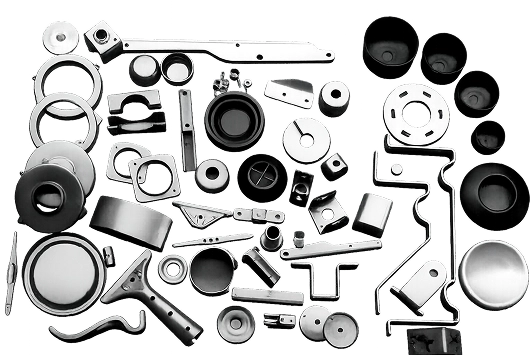

Full-service manufacturing

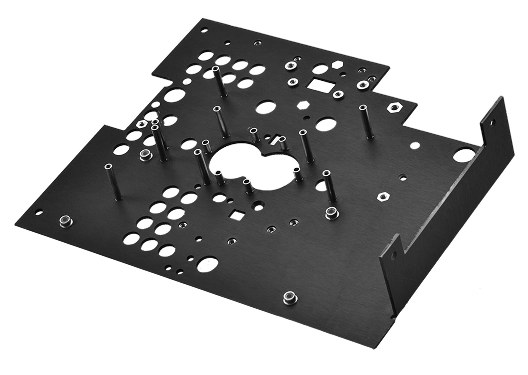

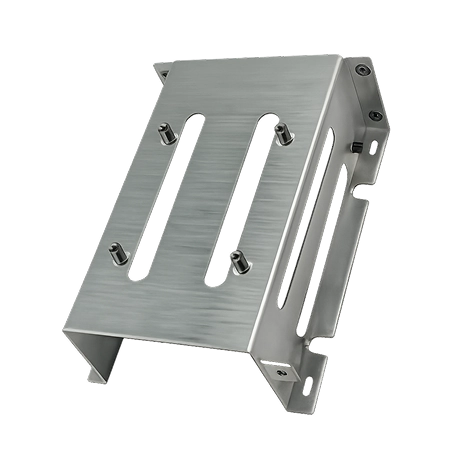

CNC laser cutting, forming, stamping, welding, machining, deburring, powder coating, assembly and packaging – all under one roof.

2-day shipping to either coast

Our central US location in DeSoto, Missouri and in-house freight services mean faster lead times.

quality

management

We are ISO 9001:2015 certified, with defect rates of 292 PPM for parts fabrication and 0 PPM for powder coating in 2025.

99%

on-time delivery

Just-in-time delivery includes inventory programs that improve cash flow, prevent shortages, and keep production lines running.

Built-in cost advantage

Low energy and operating costs combined with solar power make us globally cost competitive while providing top-tier quality.

Dependable, domestic supply chains

We help accelerate reshoring efforts and provide you with worry-free, domestic supply chain stability.

Our Capabilities

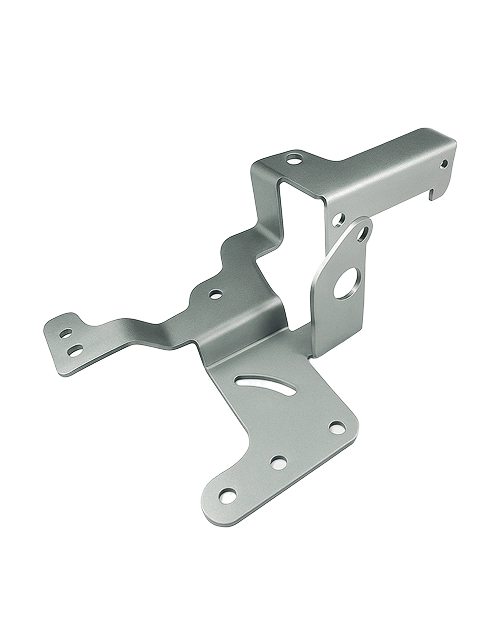

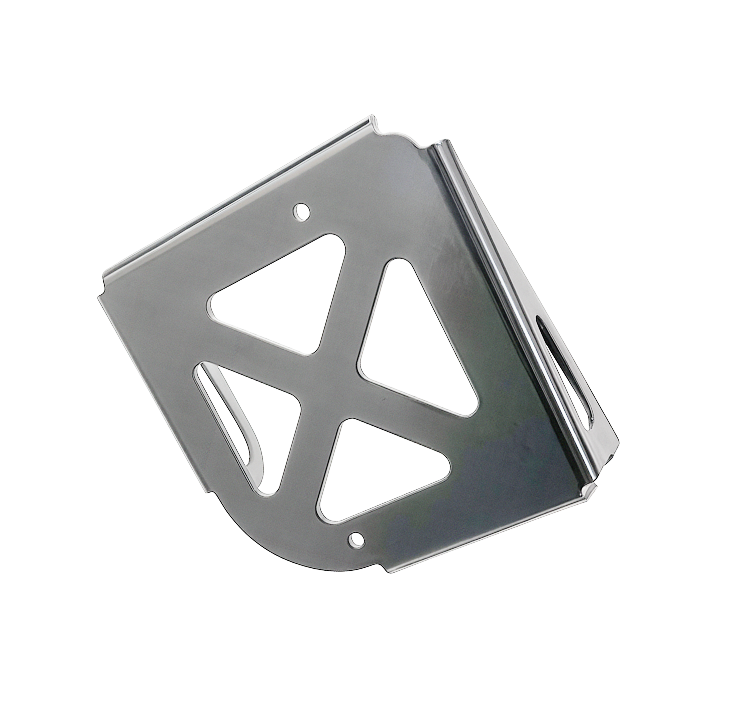

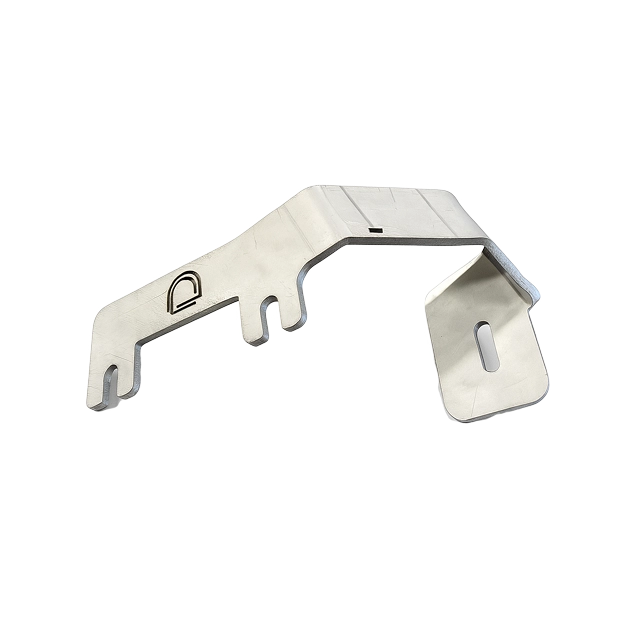

Haake Manufacturing offers Precision Custom Sheet Metal Fabrication with state-of-the-art equipment and unparalleled service.

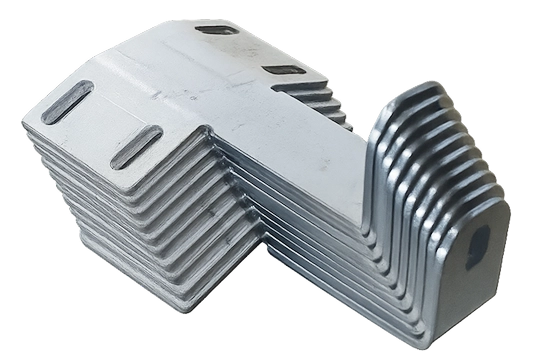

Haake offers metal stamping using AIDA punching cells up to 160 tons, supporting both progressive and single station tooling. Advanced controls, servo feeds, and monitoring systems ensure consistent quality across short and long run production. Additional presses ranging from 5 to 150 tons allow us to support a wide range of stamping requirements.

Metal Stamping

Robotic arc welding (MIG/MAG) of steel, stainless steel, and aluminum is performed using automated welding systems designed for continuous operation. These cells deliver consistent weld quality and are well suited for medium to high volume production runs.

Robotic Welding

Haake provides value added services that deliver production ready parts. Assembly, metal finishing coordination, and hardware insertion reduce supplier handoffs and simplify sourcing for turnkey components.

Secondary Services

Precision Sheet Metal Fabricators since 1948

In 1948, Fred C. Haake Sr. and his wife, Elfriede, opened a small tool-and-die shop in their St. Louis garage. With just a punch press and a commitment to quality, the couple quickly built a reputation for dependable service and became trusted partners to local manufacturers.

Since then, Haake has grown into one of the Midwest’s most respected precision sheet metal fabricators – operating out of a 100,000 square foot facility and working closely with customers across the country to deliver complex, high-volume metal parts and assemblies.

Four generations later, the garage is gone, but the mindset isn't.

The work still starts with the customer. And it still ends with precision.

Let’s get this partnership started

If you have any questions about our services or you want to request a quote, please reach out to our team. We’d be happy to schedule a call or arrange a facility tour.